The Dazzle™ 2.e

Automated CNC Coolant Manager

COOLANT SAVINGS FROM 50% T0 85% WITH AN 8 MONTH ROI.

Experience the Final Frontier in CNC Coolant Automation with the Dazzle™ 2.e: Greater Savings, Faster ROI!

Introducing Dazzle™ 2.e, the latest entry level innovation from Zebra Skimmers, revolutionizing coolant concentration mixture and delivery automation in one comprehensive system. Tailored for high-volume CNC manufacturing facilities, this patented solution slashes coolant expenses by 50% to 85%, promising a rapid return on investment within just 8 months. Discover your potential savings today by utilizing our calculator.

Discover The Dazzle™ 2.e

Drawing upon our extensive experience in CNC sump management, we proudly present the Dazzle™ 2.e – a brainchild conceived, crafted, and fine-tuned within our facilities. This patented system embodies the epitome of Industry 4.0, offering an automated sump concentration and level management system that diligently maintains both sump levels and coolant concentrations within predefined boundaries.

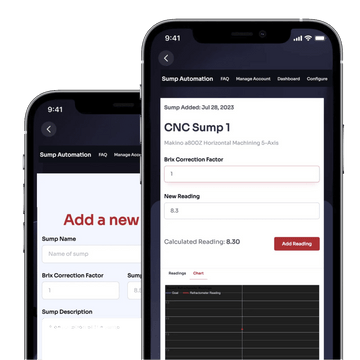

At the heart of Dazzle™ 2.e lies a sophisticated mixing algorithm that seamlessly blends neat coolant and water to achieve the exact desired concentration for each machine sump. Use the accompanied app to configure the desired concentration and sump levels. Then assign your staff roles in entering the refractometer readings. Done! Everything is managed from one simple point using our sump maintenance app.

Why Dazzle™ 2.e

Dazzle™ 2.e is flexible and configurable to manage the changing needs in a high volume manufacturing environment.

The patented Dazzle™ 2.e system includes an app that can be used on a computer, phone or tablet allowing users to manually enter the sump BRIX readings to gain valuable insights and historical data. This system is easily upgradable when you are ready to add an inline process refractometer for a FULL automation experience to our Dazzle 2.0.

Manage All Your Sumps in One Place

Seamlessly facilitate real-time monitoring and management of BRIX readings in your CNC coolant sumps. Enhance operational efficiency and extend coolant life with data tracking, intelligent alerts, and predictive analysis tools catered specifically to maintain optimal coolant concentration levels all from an App on your mobile device.

Learn More

Thank you for your interest in the Dazzle™ 2.e Automated CNC Coolant Manager. Please fill out the information below and someone will reach out to you

YES! I’M INTERESTED IN LEARNING MORE.

KEY FEATURES

Manage Multiple Sumps

Manage Sumps over 1000 feet from base unit.

System can support fluid rises up to 1.5 Feet and 10 sumps.

Measure Coolant Concentration

Dazzle 2.e uses an app to record your BRIX readings.

Continuously Monitor Coolant Concentration when New Readings are added through the app.

Level Sensing

Dazzle's 2.e Level Sensing Capabilities are based on Robust Capacitive Technology.

Capacitive Technology which is not affected by a sump’s surface crust or particles in the fluid unlike floats or other mechanical devices.

Data Collection and Analytics

View and Make System Modifications via an App on a Mobile Device.

The main Sump Graph displays each managed sump in sequential fashion and allows the user to monitor each sump in real time.